Managing a busy fleet means juggling a lot of moving parts, but your equipment’s reliability should never be one of them.

With a new season just around the corner, now is the perfect time to take the guesswork out of the shop and build a heavy equipment maintenance schedule that works as hard as you do. By leveraging telematics data to listen to what your compact and heavy equipment is saying in real time, you can have peace of mind that comes from knowing every machine is ready for the next job.

Here are the most common questions fleet managers have about transitioning to a data-driven maintenance model.

How Can Telematics Improve a Maintenance Schedule?

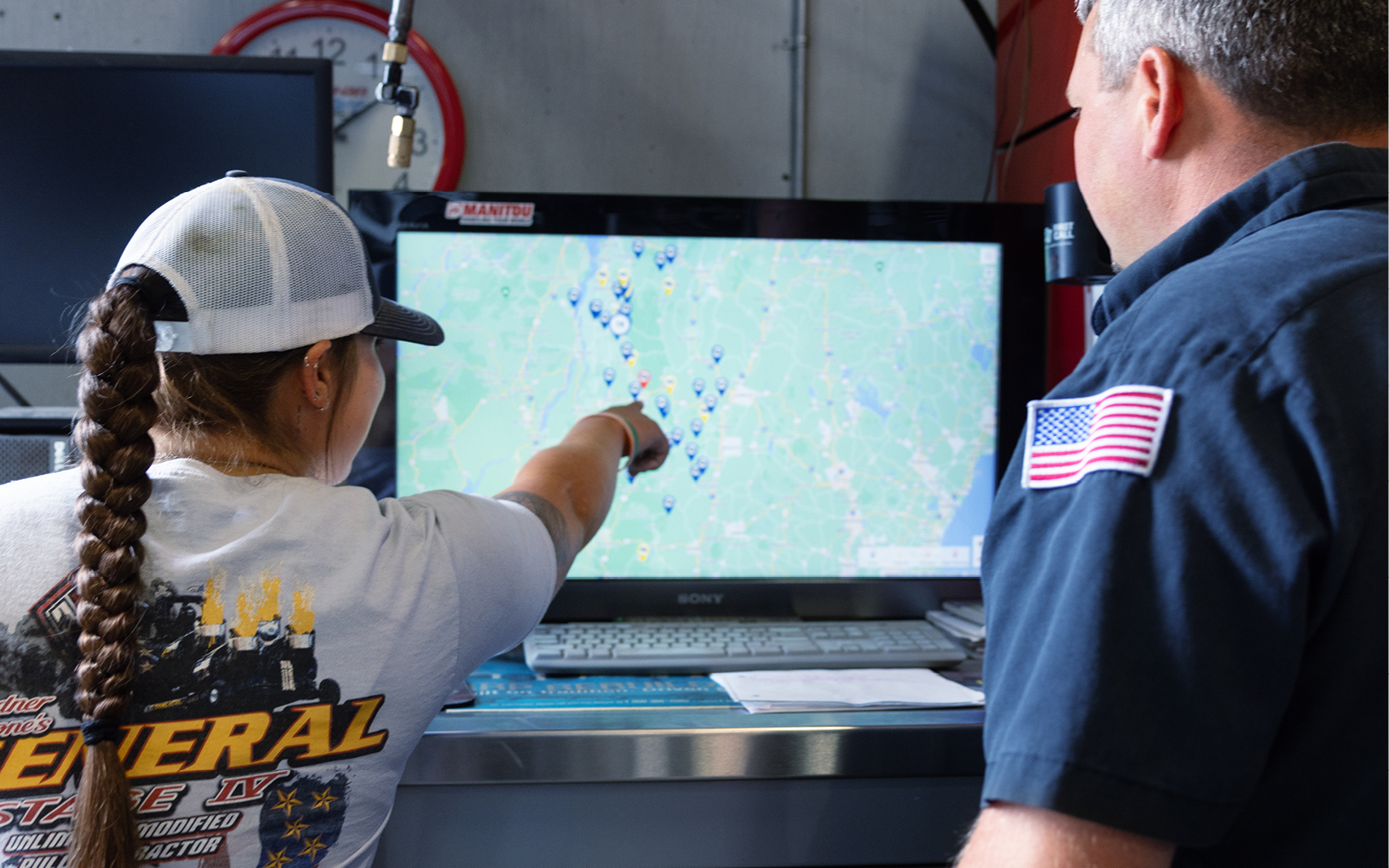

Telematics transforms a standard heavy equipment maintenance schedule into a high-precision strategy. Instead of relying on manual logs that are easily lost or forgotten, telematics can provide a live look at your equipment's health right on your phone or laptop.

By automatically tracking usage hours and fleet utilization, you can plan your service during natural breaks in your workload.

As industry veterans often point out, the power of preventive maintenance lies in this level of consistency. With telematics, you are no longer just reacting to the calendar; you are acting on real-time data to keep your fleet in peak condition.

What Maintenance Tasks Can Be Automated With Telematics?

One of the best ways to simplify your workday is to let technology handle the heavy lifting.

Through systems like MY DEVELON or Smart X-Care™, you can automate:

- Service Reminders: Set digital triggers to receive a text or email the moment a machine approaches a service milestone. This removes the need for manual tracking and ensures maintenance compliance across multiple job sites.

- Maintenance Alerts: Modern systems provide instant notifications for fault codes. This allows shop managers to address small sensor issues or pressure drops before they lead to a system failure.

- Performance Tracking: Automatically monitor engine idle time and fuel usage. High idle times often signal that a machine is being underutilized or that an operator needs additional training.

Using telematics fleet maintenance tools ensures that your service records are always up to date. This digital history is not only important for daily operations but can also increase the resale value of your equipment by providing a documented history of factory-spec care.

How Often Should Construction Equipment Be Serviced?

While every machine has its specific needs, a professional construction equipment maintenance schedule generally follows 250-, 500-, and 1,000-hour milestones.

However, the change in seasons is a critical time to reassess these intervals. Environmental factors — like extreme heat, dust or freezing temperatures — can accelerate wear on components.

For example, as summer approaches, your cooling system has to work harder to maintain safe engine temperatures. You should clean your radiator and cooling packages and check that you are using the right high-viscosity lubricants. Lubricants with higher viscosity grades are designed to withstand heat without thinning out, which prevents metal-on-metal wear during long summer shifts.

If you are prepping for a deep freeze, you should prioritize battery health and prevent fuel gelling. Refer to specialized guides on how to prep your wheel loader for winter. By aligning your service intervals with seasonal shifts, you ensure that your compact and heavy equipment remains at peak performance year-round.

Can Telematics Prevent Unplanned Downtime?

Absolutely. Many owners have discovered these 5 ways to save money with construction equipment telematics, and preventing unplanned downtime is at the top of the list.

By using predictive maintenance telematics, you can spot rising engine temperature or a specific fault code while the machine is still running. This gives you the power to schedule a quick fix during a lunch break or between jobs. Rather than dealing with a broken hydraulic system in the middle of a critical excavation, you are identifying the wear via condition monitoring and replacing the part on your terms.

How Do Dealers Use Telematics to Support Equipment Maintenance?

Your dealer service department acts as a professional partner to help you close regular maintenance gaps. Through remote diagnostics, your dealer can see the same health data you do. In many cases, they can diagnose an issue from the shop so the technician can arrive on-site with the exact part needed.

For many growing businesses, outsourcing heavy equipment maintenance to their dealer is an option to ensure factory-level care. Dealers have the specialized training and the right processes to handle things like oil disposal and DPF cleaning. You can even enroll in a planned maintenance program where the dealer manages the entire equipment maintenance schedule for you.

What Should Be on a Heavy Equipment Maintenance Checklist?

A preventative maintenance checklist is your first line of defense against wear and tear.

To keep your machines running smoothly, make sure your operators do the following as part of their daily routine:

- Remove dirt and debris from the undercarriage and engine compartment. In the summer, a dirty radiator is the leading cause of overheating and engine strain. If working in dusty environments, check air filters and blow them out as needed to prevent dirt from entering the fuel system.

- Verify oil, coolant and DEF fluid levels daily.

- Check the cab's display for any active maintenance alerts or warning codes. Addressing a fault code the moment it appears can help save on repair costs.

- Make sure backup alarms, cameras and lights are bright and functional.

Making this construction equipment maintenance checklist a positive daily habit ensures that machine uptime remains high across your entire fleet.

Don't wait for a warning light to start your maintenance journey. Contact your local dealer today for a fleet health audit. Whether you need help setting up your telematics fleet maintenance dashboard or you want to explore a customized maintenance plan, our experts are here to ensure that your equipment stays on the job and off the trailer.

By Thomas Lee, Product Strategy Manager

Thomas Lee is a product strategy manager at DEVELON. He has more than 15 years of experience working in the heavy equipment industry and leads the product management team for all heavy products.