Attachments for wheel loaders can improve your machine’s versatility, leading to increased productivity and efficiency. Learn more about some of the most popular attachments available today.

Wheel loader attachments can boost the versatility of your DEVELON machine and enhance productivity in a variety of applications, leading to greater utilization and potentially even new revenue for your business.

When looking for attachments for wheel loaders, consider the style of wheel loader you’re operating. A wheel loader with a parallel-lift linkage instead of the standard Z-bar is commonly referred to as a tool carrier.

With a parallel-lift linkage, there are two hydraulic cylinders above each arm for the bucket. The cylinders are tucked on either side, along with the parallel-lift linkage of the tool carrier, giving the operator a better view of the attachment. Additionally, the attachment stays flat when you raise it, rather than rolling backward as it would in a machine with a Z-bar linkage.

The benefit of the Z-bar linkage is greater bucket breakout force, making it preferable for digging into and moving piles.

However, you can still put pallet forks on a wheel loader with a Z-bar linkage or move a pile with a parallel-lift linkage and a bucket.

Don’t let perfect be the enemy of good. Try one of these attachments from a local dealer and see if they help you get more done with your wheel loader.

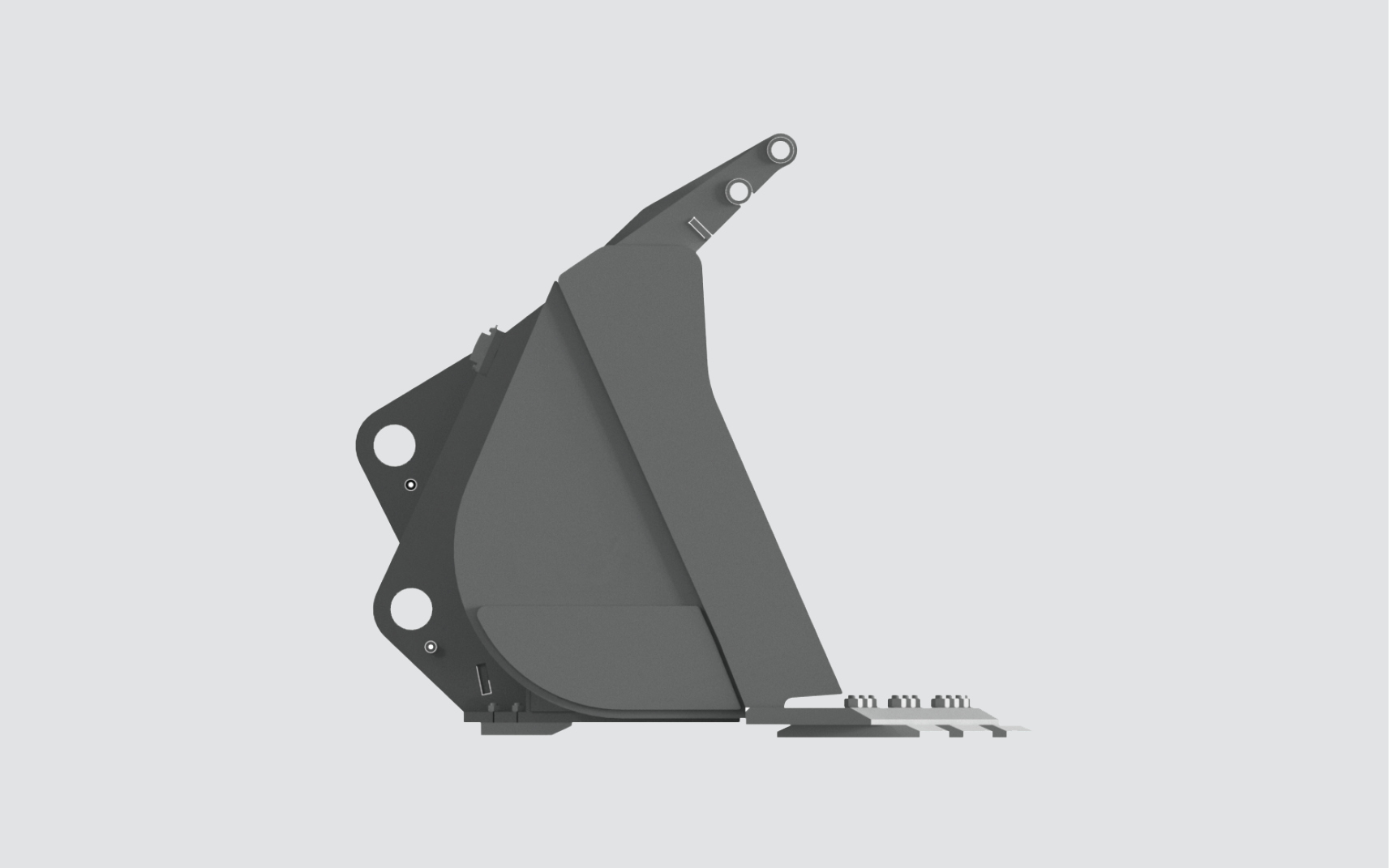

Wheel Loader Grapple Bucket

Grapple buckets are designed for moving odd-sized items. These are a must-have for working in recycling, demolition, land clearing or any other job that requires moving material that doesn’t fit neatly in a bucket. A grapple bucket is efficient for handling loose objects such as logs, rocks, brush, scrap metal and construction debris.

Look for a grapple bucket with a bolt-on cutting edge. This feature lets you easily put a new edge on the bucket, which is useful if you’re moving rough material like broken concrete and rebar.

A similar type of attachment that is popular is a grapple fork for wheel loaders. A grapple fork attachment is commonly used in construction, agriculture and other industries to handle and move various materials, typically in bulk or loose forms. A grapple fork attachment consists of two or more times that are operated hydraulically.

Wheel Loader Pallet Fork

Forks, or pallet forks, make it easier to lift and move objects on pallets. Additionally, wheel loader operators can use the pallet fork to handle materials beyond pallets, including lumber, bags of cement, pipes used in construction and items used in recycling and agricultural applications.

A pallet fork with adjustable tines can be made narrower or wider to match the pallet you need to lift.

If your wheel loader is equipped with a quick coupler, you can easily change from a pallet fork to a bucket attachment, further enhancing the loader’s versatility and efficiency.

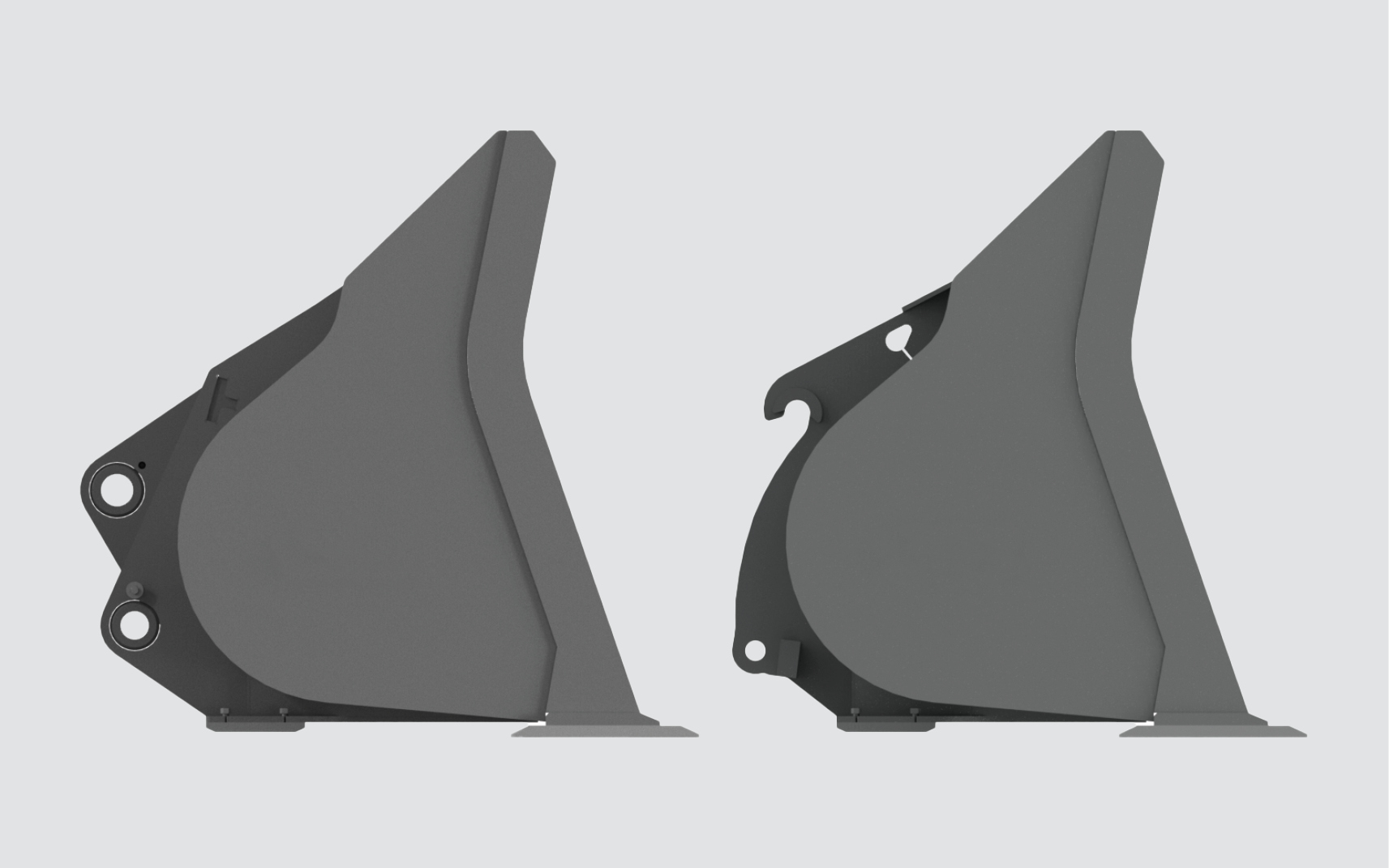

Wheel Loader Rock Bucket

Rock buckets are designed and reinforced for heavy-duty digging into rock piles or other abrasive material. Wheel loaders paired with rock buckets can clear and move rocks at construction sites and quarries more productively.

The bucket’s shape and edge configuration make it easier to scoop up and transport rocks with minimal spillage. Most rock buckets have teeth which can be welded on for added durability, and some buckets have a spade nose design to help the bucket penetrate into the pile.

A rock bucket can also handle gravel, soil and construction debris. The attachment’s versatility may reduce the need for you to own multiple specialized buckets.

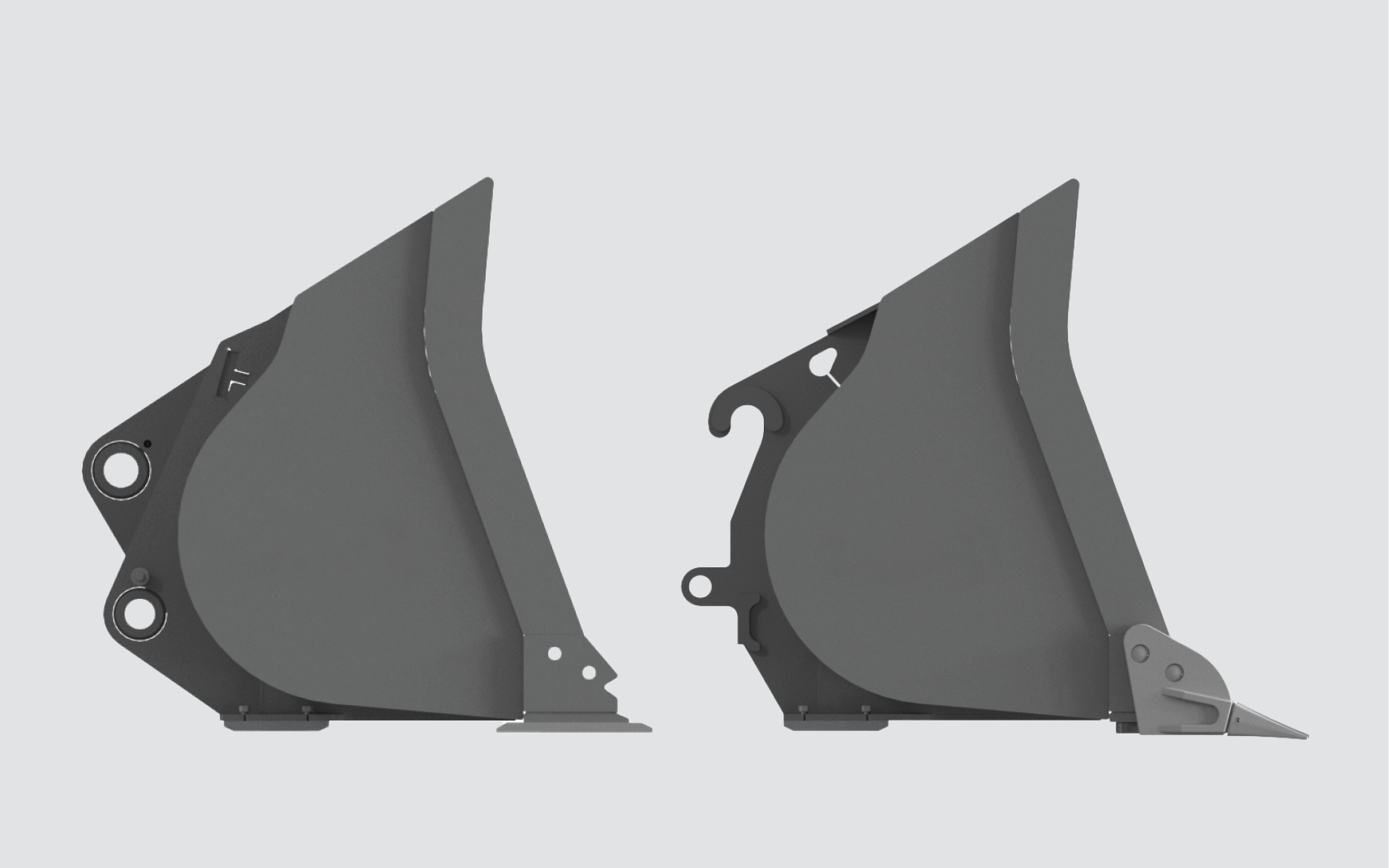

Wheel Loader Light-Material Bucket

Light-material buckets have a larger capacity for handling bulky, low-density material that is relatively lightweight, like snow, sawdust, grain, wood chips or mulch. Adding a light-material bucket is a simple way to increase your productivity when handling this type of material.

Light-material buckets are designed with wider openings for faster loading and unloading of materials and handling larger volumes of material. Additionally, light-material buckets are equipped with features to minimize material spillage during loading and transport.

Wheel Loader Quick Coupler

A wheel loader quick coupler offers benefits that enhance your wheel loader versatility and efficiency. For instance, you can connect a non-hydraulic attachment to your wheel loader without leaving the cab. If you frequently swap buckets or attachments, a quick coupler can be a time-saving investment.

A quick coupler, also known as a quick attach system, can also improve the safety of your job site. Operators no longer need to manually couple or uncouple attachments. This minimizes the risk of accidents or injuries associated with manual wheel loader attachment coupling procedures.

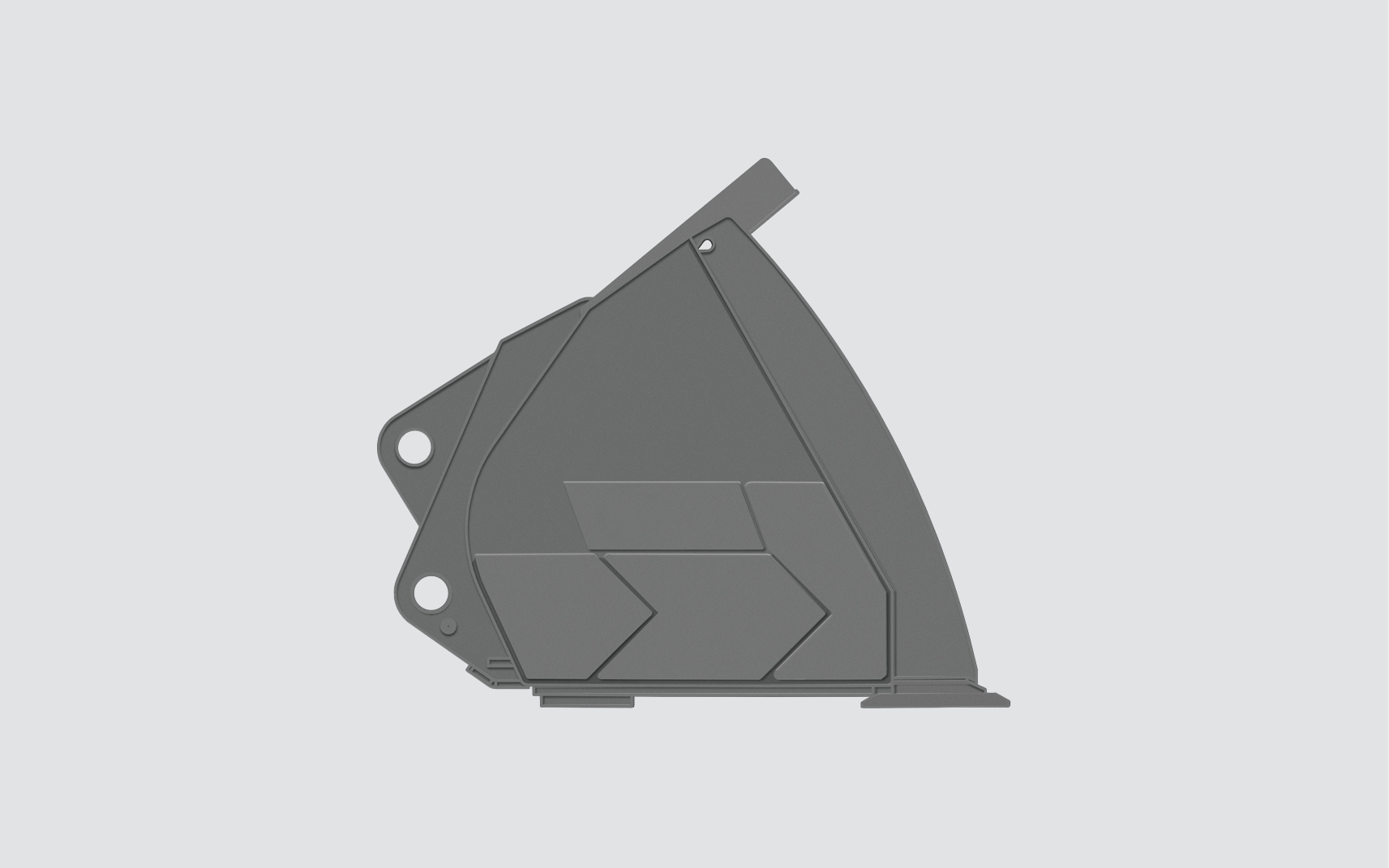

Wheel Loader General-Purpose Bucket

The general-purpose bucket, often referred to as a GP bucket, is the bucket you likely purchased with your DEVELON wheel loader. This versatile do-it-all design is effective for handling a wide range of materials, including dirt, sand, mulch and other loose materials. A general-purpose bucket is efficient for performing many everyday tasks, including digging, grading and leveling.

Is a general-purpose bucket the best bucket for your job? That depends. Tell your sales specialist how you’re using your wheel loader to see if you might be more productive with a different bucket.

For enhanced job site safety, we’ve made our exclusive Transparent Bucket technology standard on all new -7 Series wheel loaders. The Transparent Bucket technology gives operators an unobstructed view in front of the wheel loader bucket, enabling them to be more efficient as they’re working while improving job site safety for operators and other workers.

Wheel Loader Aggregate Bucket

Aggregate buckets are specialized buckets designed for handling and transporting aggregate materials like stone, sand and gravel from quarries and mines.

Wheel loader aggregate buckets are designed with a flat bottom that’s ideal for digging into a pile, providing the maximum filling and machine efficiency. A flat-bottom bucket is relatively flat and parallel to the ground when the wheel loader lift arms are positioned at ground level. The design helps operators achieve an even distribution of materials when working on construction job sites.

For added efficiency, a standard spill guard is added to the rim of the DEVELON aggregate bucket to minimize material spillage when the machine is loading and transporting contents in the bucket. The aggregate bucket spill guard also protects hydraulic lines and the machine linkage components, such as lift arms, from falling debris.

More Ways to Increase Wheel Loader Productivity

If you’re always looking to improve production KPIs, option your wheel loader with a DEVELON Smart Load weighing system. This option is ideal for applications that require accurate information about the weight of the material in the bucket. All menus and settings are integrated into the DEVELON Smart Touch screen.

The optional Load Isolation System for wheel loaders improves stability when traversing uneven terrain, resulting in reduced material loss during the transportation and loading of items.

Visit our attachment page for more details, or contact your local dealer to ask about attachments for your wheel loader.

When looking for attachments for wheel loaders, consider the style of wheel loader you’re operating. A wheel loader with a parallel-lift linkage instead of the standard Z-bar is commonly referred to as a tool carrier."Bill Zak, Wheel Loader and ADT Product Manager

By William Zak, Wheel Loader Product Specialist

William Zak is product manager for wheel loaders and ADTs at DEVELON. He has more than 20 years of construction equipment experience in product management, marketing and training. William also served in the U.S. Navy for 23 years.